Jeff Boyd discusses the multiple factors involved in optimising the machining processes of difficult-to-machine materials.

Titanium and high-temperature alloys are some of the most difficult materials to machine, due to their high strength and tough properties – plus they can also work-harden.

This means that managing heat generated, selecting the correct application-specific tool, along with using the best set of cutting parameters are all critical to optimising tool life and metal removal rates (MRR) – therefore creating overall efficiency.

Let’s consider each these factors in more detail, since they all affect one other.

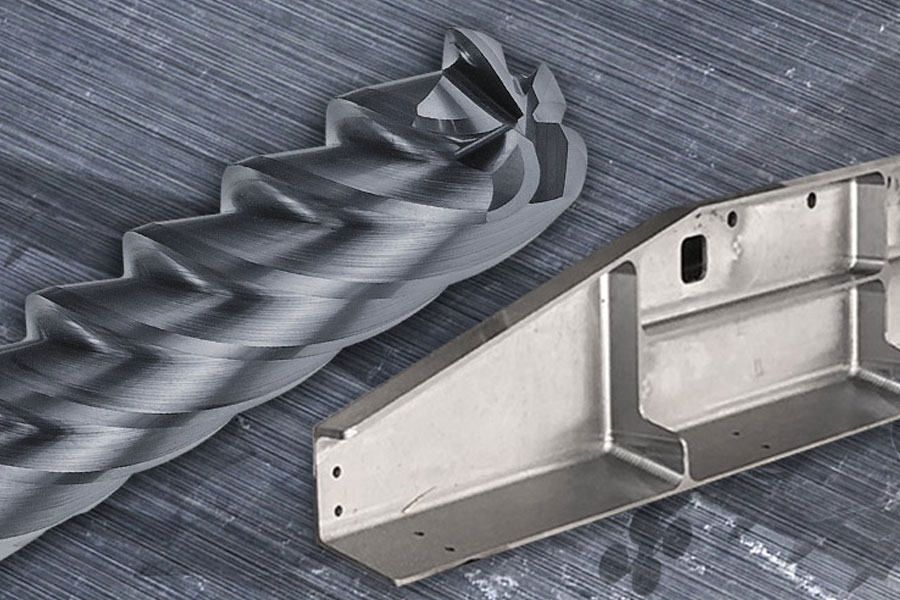

The right tool

As a first step, it’s obvious you must choose a tool optimised for this material group. Then, at the correct cutting parameters, it will support heat management in cut – as the set of its helix, relief and rake angles will have been designed to cut through material with minimal amount of friction.

Shaping and evacuating material chips in this way dissipates heat away from the cutting zone. This is important as, if heat can’t escape, the chips soften and melt – sticking to the cutting edges and resulting in shorter tool life.

The cutting parameters

High quality endmills apply very specific microgeometry through post-grinding techniques. This not only produces improved surface finish, but also a minute edge-rounding shape specifically developed to perform in a given material group.

That said, it’s very important in the Titanium and high-temperature alloys material group to stick to the manufacturer’s recommendation on feed per tooth (fz). Going above the recommended fz can lead to overloading the cutting edge. Decreasing the fz, can result in rubbing on the material – generating heat which must be avoided.

The cutting speed vc(m/min) can, however, be increased or decreased within reason – subject to the amount of step-over (ae), machine power, work-piece clamping/rigidity, coolant-to-cutting efficiency and tool holder type.

The component

Let’s consider a typical titanium aircraft part, that generally requires cavity and pocketing of deep thin walls. The most effective way to produce this type of component with optimal productivity in mind is to choose a titanium geometry tool with a cutting edge long enough to reach the full depth of the wall (ap) – matching the required fillet/corner radius on the component using dynamic milling strategies.

With dynamic milling, the radial step-over (ae) amount often permits the use of a tool with more flutes – which also supports increases in MRR and productivity. When combining all these factors, the result is the highest yield in productivity.

Consider the dynamic milling application below. Example 2 uses the longer tool – more than doubling the MRR – and also shortens the cycle time by requiring a lower number of passes.

The other factor of the component to consider is the wall straightness and surface quality requirements. For best results here, we recommend an endmill with more cutting edges or flutes, which normally means lighter step-over (ae).

Read more at https://www.suttontools.com/blog/tools/machining-titanium-and-high-temperature-alloys/